کاربردها

تولید خلاء نقش کلیدی در عملیات پالایشگاهی ایفا می کند. رایج ترین کاربرد سیستم های اجکتوری و سایلنسر های خروجی انها در برج های تقطیر این مجتمع ها می باشند. در پالایشگاه های نفت هم زمان…

محصولات این شرکت بطور گسترده ای در صنایع پتروشیمی و شیمیایی قابل استفاده می باشد. به منظور دستیابی به خلاء مورد نیاز خطوط پروسس کارخانه های پتروشیمی و شیمیایی، صنادید توس با ساخت تجهیزات مختص، الزامات پیچیده در…

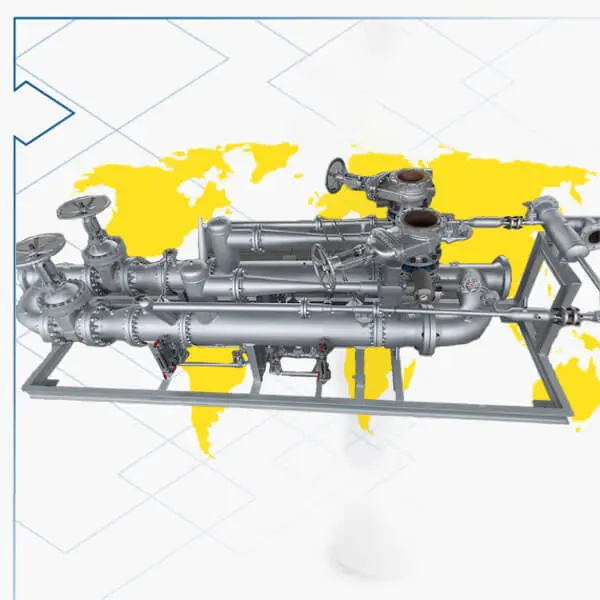

سیستم های تولید خلاء در انواع مختلف، اجکتور های بخار و اجکتور های آبی شرکت صنادید توس از تجهیزات مورد نیاز مبرم در واحد های تولیدی نیروگاهی می باشند. این تجهیزات طی سال های متمادی نوآوری شده…

در کارخانه های فولاد مواد خام است در واحد موسو به RH و در طول متالورژی ثانویه پالایش و احیاء می شوند. وجود خلاء و فشار پایین در واحد RH موجب ایجاد ماکزیمم کیفیت در آن قسمت می شود. این پدیده به این دلیل اتفاق می افتد…

سیستم های خلاء شرکت صنادید توس در مراحل مختلف پروسس صنایع غذایی از جمله خشک کردن، تقطیر، تفکیک سازی و همچنین استری کردن در طول تولید روغن خوراکی، بیودیزل، اسیدهای چرب، صابون و گلیسیرین پرکاربرد می باشد…

تولید کاغذ نیاز به یک پروسه کنترل فرآیندی بسیار دقیق و حساس می باشد. ترمو کمپرسور های از نوع جت بخار ساخته شده در شرکت صنادید توس یک عامل عمده و کلیدی برای محصولات با کیفیت بالا در این صنعت می باشد…

پروژه های ما

مشتریان ما

اخبار شرکت

A new contract for delivery Methanol Reactor’s start-up Ejectors

Due to previous success of Sanadid Company in designing and manufacturing of the heating-up ejectors for methanol reactors, this company successfully signed a vital contract

Entering the Iran National Oil Approved Vendors Long List

Sanadid Company succeeded in obtaining approvals to enter the long list of National Iranian Oil Company (EP) for its all products as well. Now our

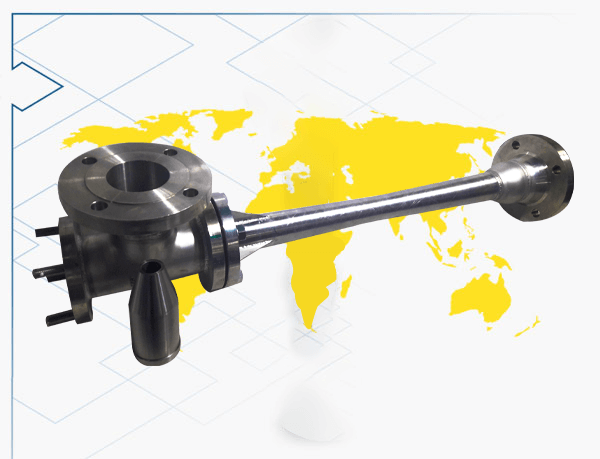

Advanced Design of Spindle Ejectors

A purchase order has been completed successfully by Sanadid Company to design and fabricate spindle start-up ejector heaters for Methanol Reactors for the first time